Home

Manufacturer List

AccuFill

Aerosol Can Filling Lines

Arbo Engineering

ASTI

Crandall International

Edwards Engineering Corp.

Environmizer Systems Corp

Fourier Systems Ltd.

Jersey Crusher, Inc

Kinematica

LEWCO

M&W Industries

SMICO Manufacturing Co.

Vincent Corporation

|

|

Enviromizer:

Prevent Scale and

Improve efficiency in

Heat-exchange applications

|

Enviromizer: Guaranteed to Give You a Competitive Edge: Save Operating Costs by:

* Minimizing Scale and MilkStone

* Improving Heat Transfer to Reduce Fuel

* Extending Production Runs

* Reducing CIP Time and Chemical Use ....... in Food & Dairy Operations

The Enviromizer prevents or retards scale and milk-stone buildup on heat exchange surfaces in dairy and beverage evaporators,

pasteurizers, and HTST units.

The reduced (or prevented) deposits improve heat transfer and reduce fuel costssignificantly,

extend time between C-I-Ps, and reduce CIP time and chemical use.

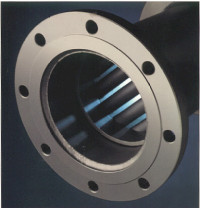

The Enviromizer does this by using state-of-the-art permanent rare-earth magnets to create an extremely high-strength magnetohydrodynamic (MHD) field. Properly sized and configured in a flow line, the Enviromizer acts to alter the structure of the calcium carbonate and sulfate salts that form when dairy and beverage products are heated. This MHD field does not

prevent forming calcium salts, but it does alter their structure from the crystalline calcite form that causes hard scale to the aragonite form that either stays in suspension or produces less scale which is easier to clean. In fact, the Enviromizer is deliberately configured to

promote forming Ca salts, but in the aragonite form.

Enviromizers are easy to install and remove for inspection and validation. They need no external energy source and have no moving parts.

The MHD field does not change the liquids chemical composition or biological properties. They are USDA-approved with 304SS sanitary-design product-contact surfaces.

Applications include: Single- and multi-effect evaporator preheaters & heat exchangers

HTST pasteurizers

Concentrators

The Enviromizer saves money in down time and heating expense because it:

Extends operating run-time and production volume between CIPs from 120 to 150%

Shortens flush/cleaning cycles to save time and reduce CIP chemical use

Cuts utility costs because scale is reduced or eliminated and heat transfer improved

The Enviromizer is offered with a guaranteed-savings trial lease program. You avoid capital expense outlay and finance the system by offsetting operating costs.

Enviromizers are in usesaving costsat San Joaquin Dairyman, Foster Farms, Danish Creamery, Kraft, and others.

Additionally, Beatrice in Turlock recently installed 14 Enviromizers in their 7-effect Wiegand multi-pass-evaporator and at the 210 150 gpm superheater. Foster Farms uses an Enviromizer at the multiple effect evaporator in their Kansas plant, reported to be ..running great. Avonmore West in Gooding, ID has minimized use of NaOH and neutralization chemicals during CIP.

Please let me know if youd like specific contacts for reference. You can

review a chart [click] which tabulates projected savings for a boiler operation

and the effect of scales.

The Enviromizer is priced to be a cost-savings item affordable within your operating budget rather than as a capital-expense cost. It is justified on a savings-guaranteed basis through measurably lower fuel cost, longer production runs between CIP, & faster clean-out with less chemical.

Interested ?

Please click to see how the trial and lease program is guaranteed to save you operating and maintenance

costs. |